A Complete Guide to Keyboard Keycaps

This comprehensive guide details the different types of keyboard keycaps, their materials, manufacturing processes, and customization options. It explores popular plastics like ABS and PBT, advanced methods like 3D printing, and artisanal hand-molded keycaps. Additionally, it discusses specialty options such as POM and rubber-coated keycaps, providing valuable insights for keyboard enthusiasts and gamers. Perfect for those looking to personalize their keyboards, this article explains everything you need to know about keycap selection and design trends.

A Complete Guide to Keyboard Keycaps

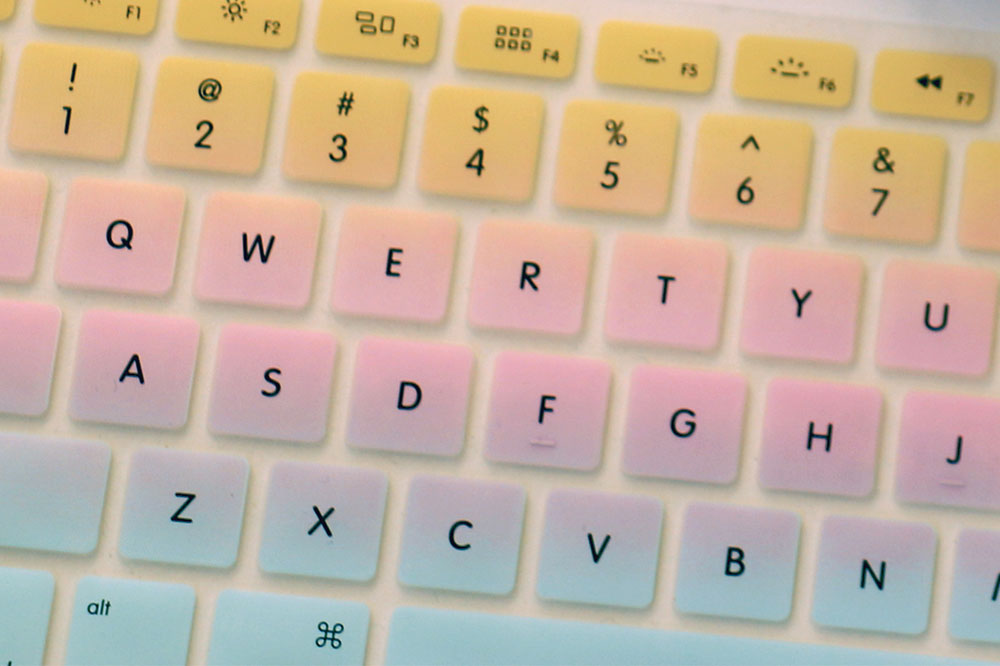

Keycaps are the plastic covers placed on keyboard switches that users press to input data. They display the characters, symbols, or functions associated with each key. Today, keycaps are popular among keyboard enthusiasts who personalize their setups with various shapes, colors, and textures. Custom keycaps have become a trend in the typing community, allowing users to enhance both aesthetics and feel.

What are Keycaps Made Of?

The manufacturing process for keycaps typically involves thermoplastic injection molding, where melted plastic is pressed into steel molds. Various plastics are used to produce different types of keycaps.

ABS:

Acrylonitrile butadiene styrene, or ABS, is the most common plastic for keycaps due to its affordability and availability. It’s widely used for its ease of manufacturing and cost-effectiveness.

PBT:

Polybutylene terephthalate (PBT) is increasingly favored for its durability and resistance to shine over time. PBT keycaps have a textured feel and are often found in aftermarket collections, though they tend to be more expensive.

3D Printed Keycaps:

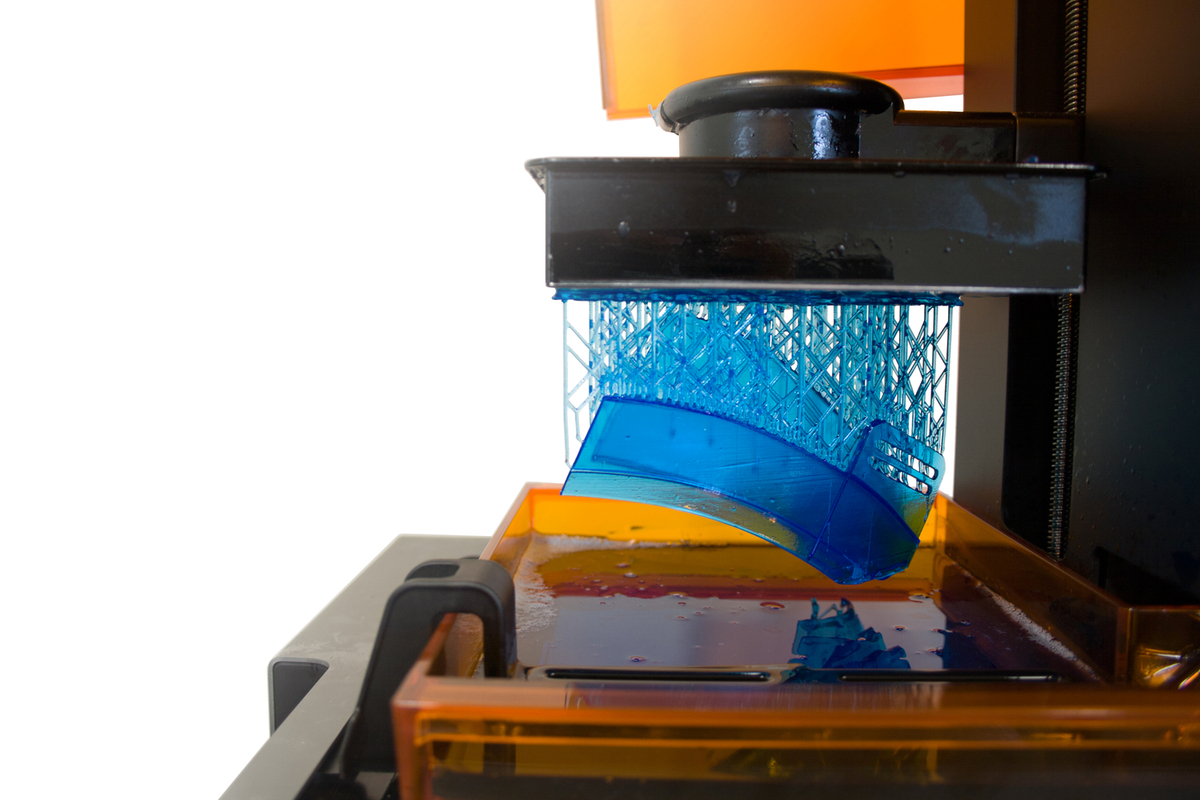

Advances in 3D printing allow for customized keycaps in various shapes and colors. With access to a 3D printer, users can create unique designs tailored to their preferences.

Hand-Carved Keycaps:

These are crafted by artisans using molds and casting techniques, making each piece highly unique and often expensive. The intricate process involves shaping, molding, and resin casting, resulting in collectible and artistic keycaps.

POM:

Polyoxymethylene (POM) is a rare choice for keycaps due to its durability but slippery texture, leading to limited use in the market.

Rubber Coated Keycaps:

These are plastic keycaps with a rubber overlay, providing enhanced grip for users. They are particularly favored by gamers seeking better control during intense gameplay.

Note:

Our blog offers diverse informational content across various topics, supporting readers with thorough research and insights. However, articles should not be considered definitive, and the site cannot be responsible for discrepancies or inaccuracies. Readers are encouraged to verify information independently for the most accurate and beneficial details available online.