Common Materials Utilized in Air Filtration Systems

Discover the key materials used in air filters, including activated carbon, polyurethane foam, stainless steel, and paper. Learn how these materials improve air quality in various applications, from aircraft engines to building ventilation. Understanding the appropriate filtration materials helps optimize air purity and device performance through tailored solutions based on pollutant type and environmental needs.

Common Materials Utilized in Air Filtration Systems

Air filters play a crucial role in improving air quality by removing contaminants such as dust particles, bacteria, and gases. They are vital components in aircraft engines to ensure air purity and are also used extensively in building ventilation systems. With advancements in technology, air filtration methods have significantly evolved, particularly through breakthroughs in aerodynamics and materials science.

The choice of filtering material depends on the specific application and types of pollutants targeted.

The composition of airborne particles varies by location, making it essential to select appropriate filtering materials for different environments. Key materials used include:

Activated carbon: Charcoal-based filters absorb odors and gaseous pollutants like ozone.

Polyurethane foam: Thick foam filters trap large dirt particles, previously popular in rally racing vehicles but gradually being replaced by modern materials.

Electrostatic charge: Utilized in air ionizers, high electric charges attract and eliminate airborne pollutants.

Stainless steel: Mesh filters come in various pore sizes tailored to different filtration efficiencies.

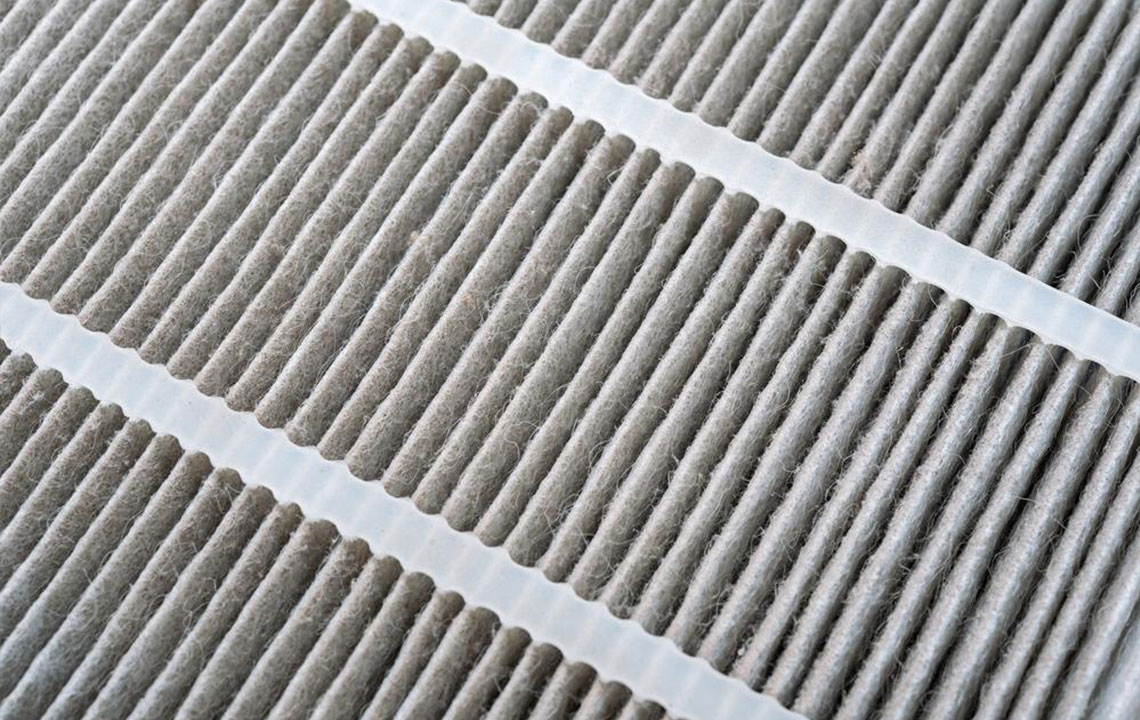

Paper: Cost-effective and easy to manufacture, pleated paper filters are common in automotive air filtration.

Cotton: Recently gaining attention, cotton filters are used in air compressors, though less widely.

Other materials such as polyester, oil baths, and water baths are used in specific applications. Often, multiple materials are combined to achieve optimal pollutant removal, with choices driven by budget and performance needs.

Selecting the right air filter material is essential for achieving desired air purity and ensuring the efficiency of filtration devices.

Note:

Our website offers diverse informational content across various categories, providing valuable insights based on research and data. However, articles should not be considered definitive. We are not responsible for discrepancies or inaccuracies that may appear elsewhere. Additionally, some schemes or offers may not be covered on our platform that could be beneficial to our readers.