Key Industrial Machinery in Plastic Manufacturing

This article examines essential industrial equipment in plastic manufacturing, focusing on their functions, applications, and significance. From laser cutters to blow molding machines, learn how these tools optimize production, improve quality, and support the industry's global growth. Proper maintenance of these machines is crucial for efficient and high-quality output, aiding manufacturers in meeting rising demand and technological advancements in plastics.

Key Industrial Equipment Utilized in the Plastic Sector

The plastic industry is experiencing rapid expansion, making specialized machinery essential for streamlined production. These machines significantly enhance manufacturing efficiency, lower costs, and improve product quality. Various types of equipment are employed at different production stages, each serving specific functions. This article explores the main machinery used in plastic manufacturing and their applications.

Overview of Plastic Equipment

Plastic manufacturing encompasses a range of machines, often grouped into four categories: plastic forming equipment, auxiliary processing tools, secondary processing machinery, and compounding devices. Additional machines like injection molding units, film extruders, vacuum formers, rotational molders, granulators, shredders, and CNC routers are integral to various processes such as cutting, engraving, and shaping plastics.

Machines in plastic production are selected based on their efficiency and precision. Below are some pivotal machines in the industry:

1. Laser Cutting System

This machine is vital for detailed design work and precise cuts in plastics. Operating through CNC automation and controlled by CAD software, laser cutters produce clean, accurate incision lines by directing high-powered laser beams onto the material. They are widely used in industrial manufacturing for engraving, cutting metal sheets, piping, and structural components, accommodating both small and large projects.

2. Capsule Filling Equipment

Used primarily in pharmaceuticals, capsule fillers automate the process of filling empty capsules with medicinal ingredients. They are categorized into manual, semi-automatic, and fully automatic machines, suitable for small-scale or large-scale production. These devices efficiently fill, cap, and eject capsules while maintaining high hygiene standards.

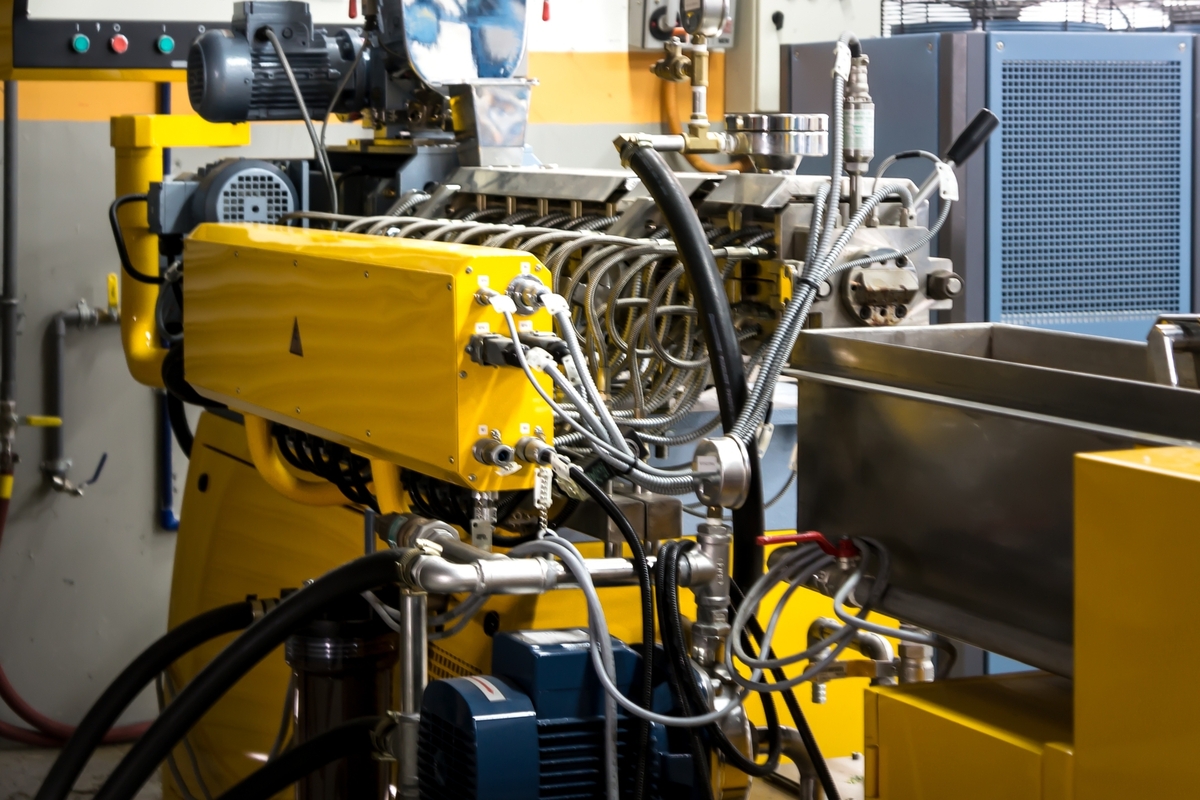

3. Hollow Product Forming Machine

Also known as blow molding machines, these devices produce hollow items like bottles and containers. By blowing compressed air into heated plastic molds, they create intricate shapes used in cosmetics, food packaging, and more. Available in extrusion, injection, and specialized variants, these machines feature components like extruders, clamps, hydraulic and pneumatic systems for high performance and ease of operation.

4. PVC Profile Extruder

This equipment is specialized for shaping plastics into profiles, pipes, sheets, and composites. Employing single or double cylinders, it manages delicate materials like PVC efficiently. The selection of screw and barrel materials—such as nitrided or carbide coatings—is critical to ensuring durability and quality in extrusion applications.

The global demand for plastic products continues to rise, emphasizing the importance of well-maintained industrial machinery. High-quality equipment ensures consistent output, reduces production time, and guarantees product excellence, supporting the growth of the plastic industry worldwide.