Comprehensive Guide to PVC Extrusion Machines and Pricing Options in Mexico

This guide offers a detailed overview of PVC extrusion machines available in Mexico, detailing types, features, and price ranges. It helps manufacturers choose suitable equipment to optimize production, whether starting small or scaling up to high-speed systems. Key factors include capacity, material handling, and energy efficiency. Connecting with reputable suppliers ensures quality and support, making this a valuable resource for plastic industry players aiming to enhance their manufacturing capabilities efficiently and cost-effectively.

Comprehensive Guide to PVC Extrusion Machines and Pricing Options in Mexico

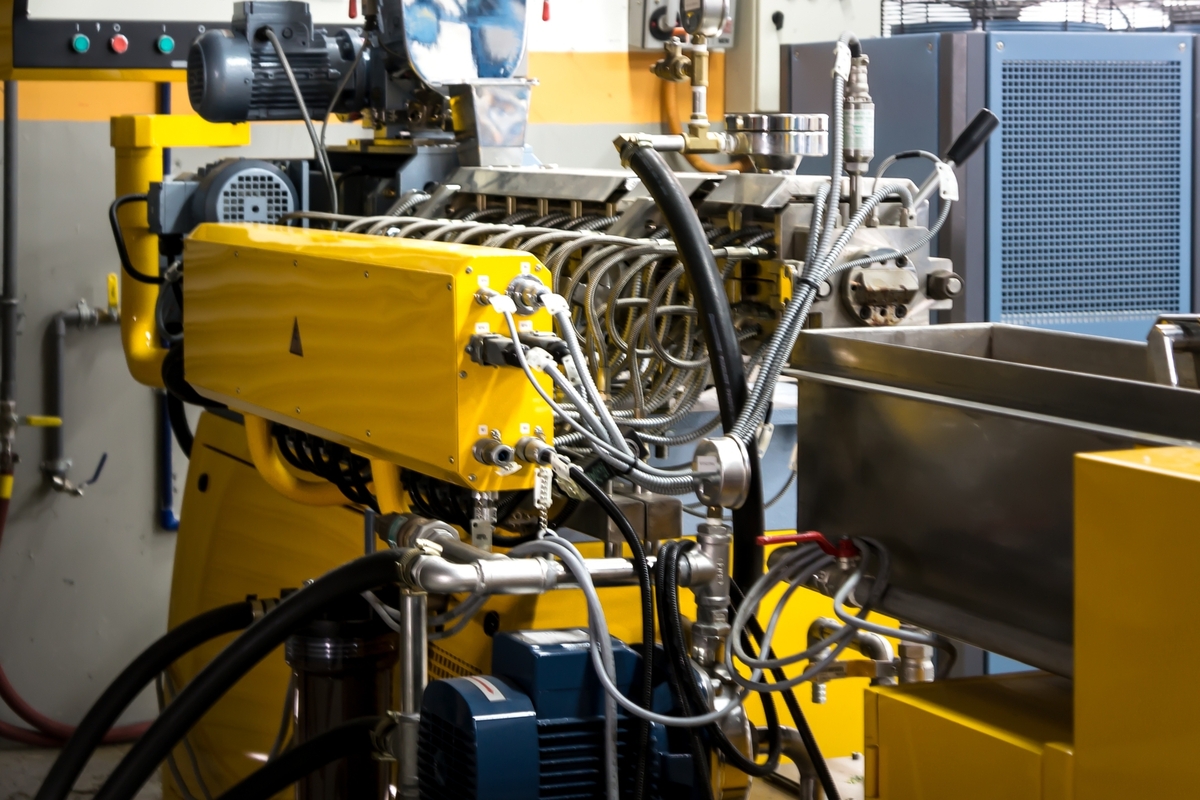

PVC extrusion equipment plays a vital role in the plastics manufacturing industry, enabling the production of items such as pipes, profiles, and sheets. Mexico’s growing plastic sector offers a wide selection of these machines, catering to different production needs. This article provides an in-depth look at the various types of PVC extrusion machinery available in Mexico, along with their price ranges, helping buyers make well-informed choices.

1. Single Screw Extruders

Overview:

Single screw extruders are popular for their simplicity and efficiency. They feature a single helical screw within a barrel, which heats and pushes PVC material through a die to shape it.

Advantages:

Affordable for basic PVC manufacturing tasks.

Easy to operate and maintain.

Ideal for producing pipes, sheets, and simple profiles.

Price Range:

In Mexico, single screw extruders typically cost between $20,000 and $80,000, depending on capacity and features.

2. Twin Screw Extruders

Overview:

These units feature two screws that intermesh, providing superior mixing and handling, especially for PVC compounds with additives.

Advantages:

Better blending and homogenization of materials.

Higher output efficiency.

Suitable for producing complex profiles and high-quality pipes.

Price Range:

Costs for twin screw machines in Mexico range from $50,000 to $150,000, influenced by screw design, brand, and capacity.

3. Conical Twin Screw Extruders

Overview:

Designed with conical screws, these machines enhance feeding and melting, making them ideal for processing PVC with complex formulations.

Advantages:

Improved feeding and melting efficiency.

Excellent for larger pipes and complex geometries.

Energy-efficient operation.

Price Range:

The cost in Mexico spans from $60,000 to $180,000, based on specifications and manufacturer.

4. Parallel Twin Screw Extruders

Overview:

Featuring parallel screws rotating synchronously, these machines deliver consistent extrusion and high dispersion for high-quality profiles.

Advantages:

Reliable and uniform material processing.

Ideal for producing premium PVC profiles and sheets.

High efficiency and throughput.

Price Range:

The price in Mexico sits between $70,000 and $200,000, depending on machine capacity and features.

5. High-Speed PVC Extruders

Overview:

Engineered for rapid production, these high-speed machines maximize efficiency with advanced controls, perfect for large-scale manufacturing.

Advantages:

Significantly increased production capacities.

Precise operation with modern control systems.

Ideal for high-volume PVC output.

Price Range:

Prices start at $100,000 and can go up to $300,000 in Mexico, based on speed and features.

6. Compact PVC Extruders

Overview:

These space-saving machines are suited for small and medium-sized producers, offering efficiency without requiring much space.

Advantages:

Compact design for limited spaces.

Cost-effective for medium-scale production.

Easy to set up and operate.

Price Range:

Available from $15,000 to $50,000 depending on specifications and manufacturer.

Choosing the appropriate PVC extrusion machine is essential for optimizing production and ensuring high-quality output. Mexico’s diverse market allows businesses to select from various options, from basic single screw systems to advanced high-speed models, aligning with their budget and production goals.

When purchasing, consider factors like capacity, material handling, energy efficiency, and after-sales support. Partnering with reputable suppliers ensures reliable performance and maintenance, helping manufacturers stay competitive in the industry.

Understanding the different types and prices of PVC extrusion machinery in Mexico enables informed decision-making, supporting growth and production excellence in the plastics sector.

Note: Prices are estimates and subject to variation based on supplier and customizations. For precise quotes, consult local manufacturers. This article provides informational insights and is not professional investment advice.